To maintain the competitive edge and enhance efficiency, manufacturing organizations must adopt crucial emerging technologies like AI, digitization, and big data.

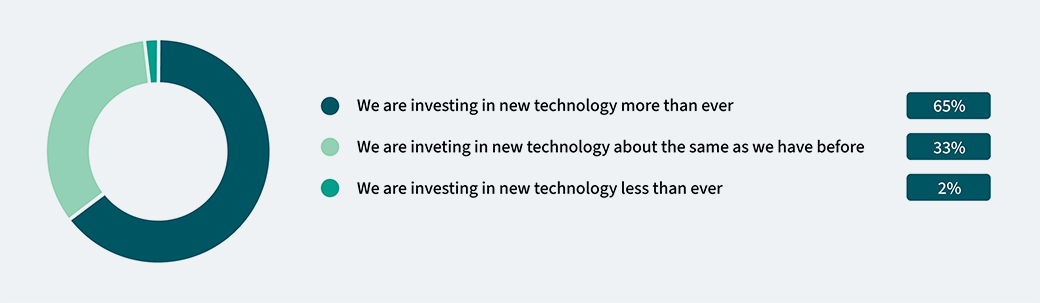

65% of respondents report increased investment in new technology compared to last year, up from 55% in 2023. This indicates a clear trend toward technological adoption as manufacturers prioritize modernization to stay competitive. Only 33% say their investment remains the same, and just 2% are investing less than before.

State of investments in new technology over the past 12 months:

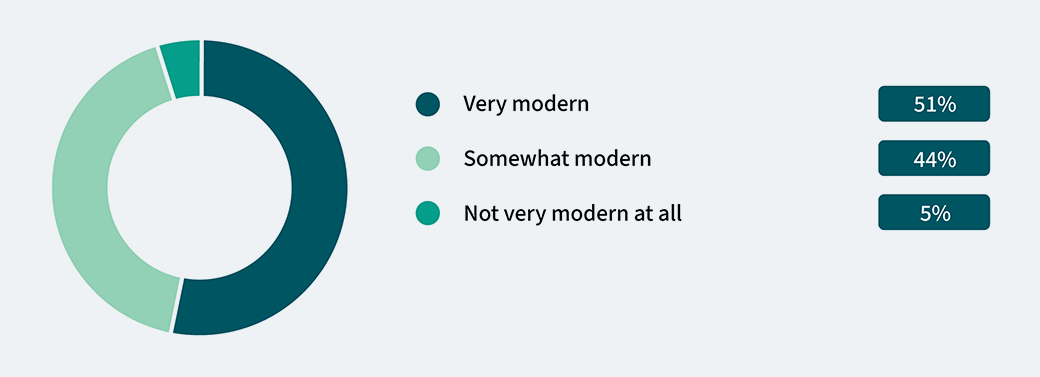

51% of respondents believe their company is “very modern,” a slight decrease from 58% in 2023. An additional 44% say their company is somewhat modern, while 5% view their organization as not modern at all. This decline suggests the competitive landscape is shifting, with modernization efforts remaining vital.

Compared to other companies, how “modern” would you say your operation is?

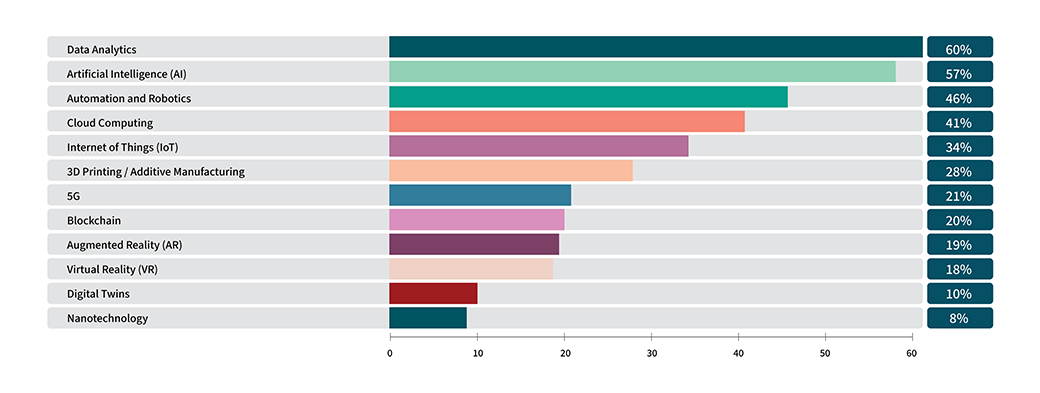

The leading technologies adopted by modern manufacturers are data analytics (60%), AI (57%), automation and robotics (46%), cloud computing (40%), and IoT (34%). These percentages have remained relatively consistent with 2023 findings, reflecting the sustained focus on data-driven decision-making and automation in the industry.

Which modern technologies and tools is your factory using? [Select all that apply]

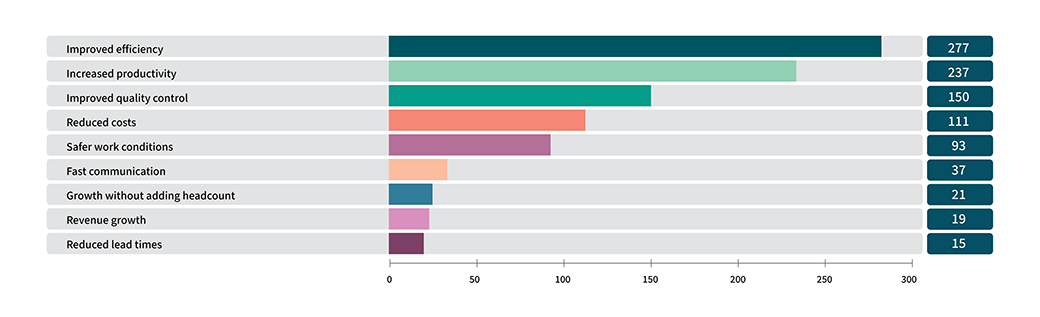

Manufacturing modernization has led to notable improvements: 30% report increased efficiency, 24% improved productivity, 16% improved quality control, 12% reduced costs, and 10% enhanced safety conditions. These trends align with 2023 results, where similar priorities were identified, though improvements in quality control have seen a slight increase.

What is the #1 improvement modernization has brought to your company?

Top Four Areas of AI Implementation

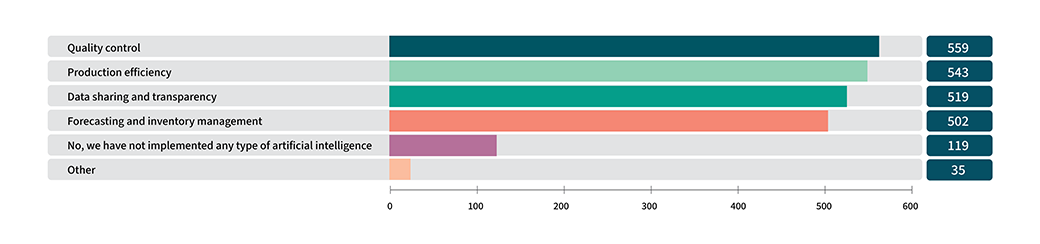

Top Four Areas of AI ImplementationAI is primarily used in quality control (55%), production efficiency (54%), data sharing and transparency (51%), and forecasting and inventory management (50%). This closely mirrors the top areas of AI use in 2023, demonstrating a continued reliance on AI to streamline production and enhance data transparency.

Has your organization implemented AI to improve any of the following areas? (Select all that apply)

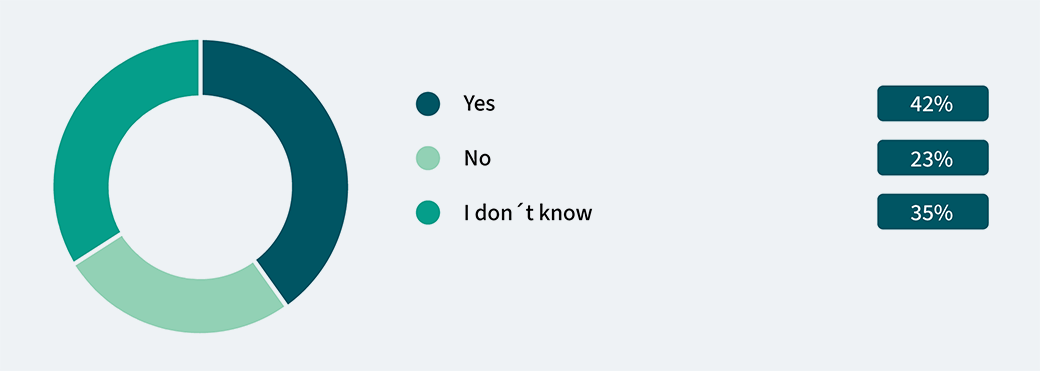

42% of respondents expect future opportunities to implement AI, down slightly from 45% in 2023. Meanwhile, 23% do not see any AI potential, and 35% are undecided. This indicates that while AI adoption is advancing, there remains uncertainty in certain sectors about its future applications.

Do you see opportunities for Artificial Intelligence to be implemented at your organization?

When asked to elaborate on the potential applications where AI could be implemented, respondents answered with the following, in their own words:

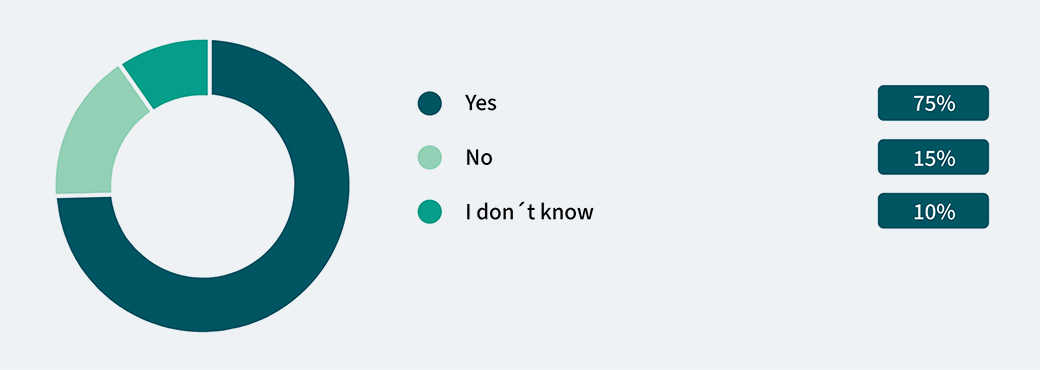

75% of respondents say their company embraces a data-first strategy, an increase from 67% in 2023. This shift highlights the growing importance of data in decision-making processes, helping companies streamline operations and achieve better outcomes.

Would you say your company embraces a “data-first” strategy?

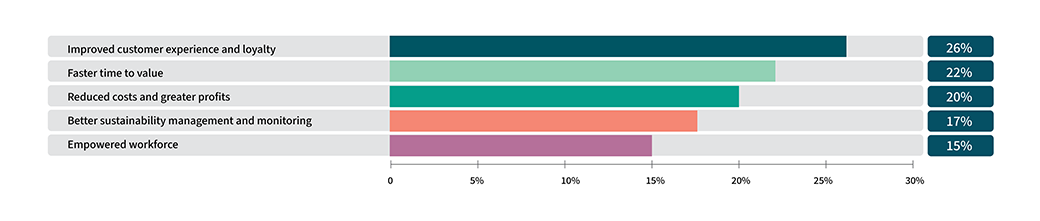

Among respondents whose companies embrace a data-first strategy, 26% report improved customer experience and loyalty, 22% cite faster time to value, and 20% point to reduced costs and greater profits as key benefits. This is a notable increase in the recognition of cost-related advantages, up from just 6% in 2023, reflecting the growing impact of data-driven strategies on operational efficiency and profitability.

What has been the biggest benefit of your data-first strategy?